Recent Posts

-

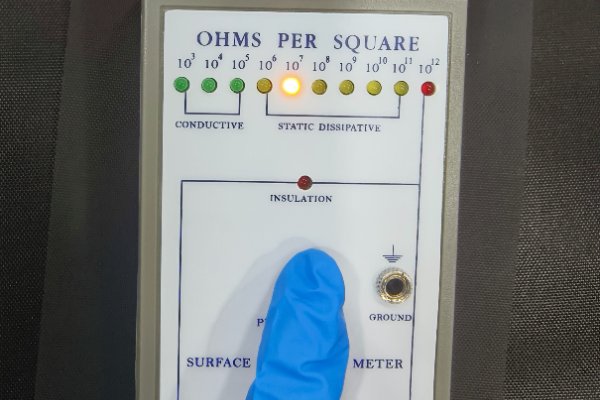

ESD Electrically Conductive Silicone Sponge Sheet Static Dissapative Gaskets

An Electronic Conductive Silicone Sponge Sheet is a specialized elastomeric material engineered to provide both electrical conductivity and environmental sealing in a soft, compressible form. It combines the flexible, durable properties of silicone rubber with the electrical properties of conductive fillers, all within a sponge (foam) structure. Electrically Conductive Silicone Sponge Rubber Roll and Sheet Gaskets Static Dissapative Application - Protection (cover) of Electronic Devices from

09/18/2025

-

UL 94 V0 Fire-Retardant Silicone Sponge Sheet

Fire-retardant, closed-cell silicone foam sheet certified to UL 94 V-0 standard.

06/18/2025

-

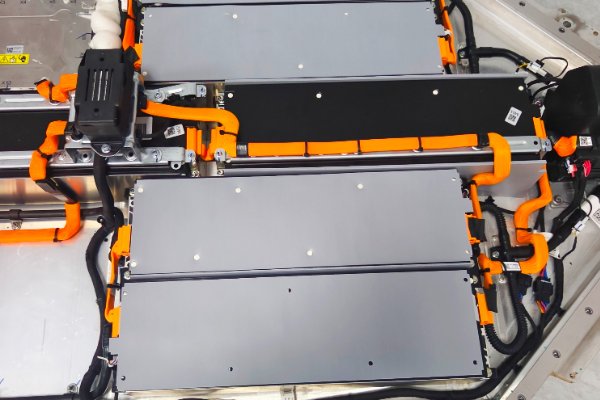

UL 94 V0 Battery Sealing Silicone Foam Fire Safe

UL 94 V0 Fireproof Battery Sealing Silicone Sponge Sheet Fire Safe

06/18/2025

-

Thermally Conductive Silicone Sponge Rubber Roll and Sheet Gasket

Thermally conductive silicone sponge is a closed cell, conformable gap filler offering designers thermal conductivity for high and low temperature applications. Because of its unique characteristics, the material is used in many applications including, heat press, power electronics, computers, telecommunications, military and medical electronics.

05/25/2023

Silicone Heatpress Pads

Dongguan Moonus Technology Co.,Ltd.

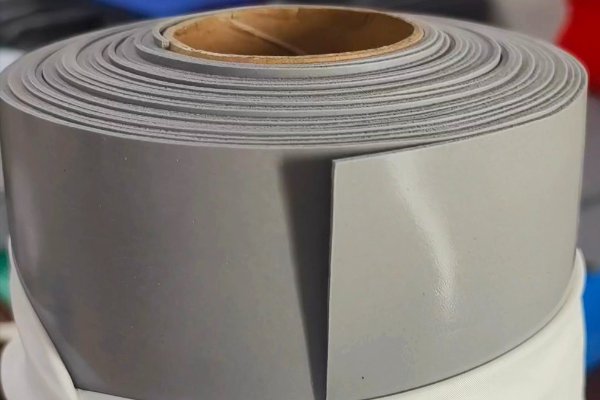

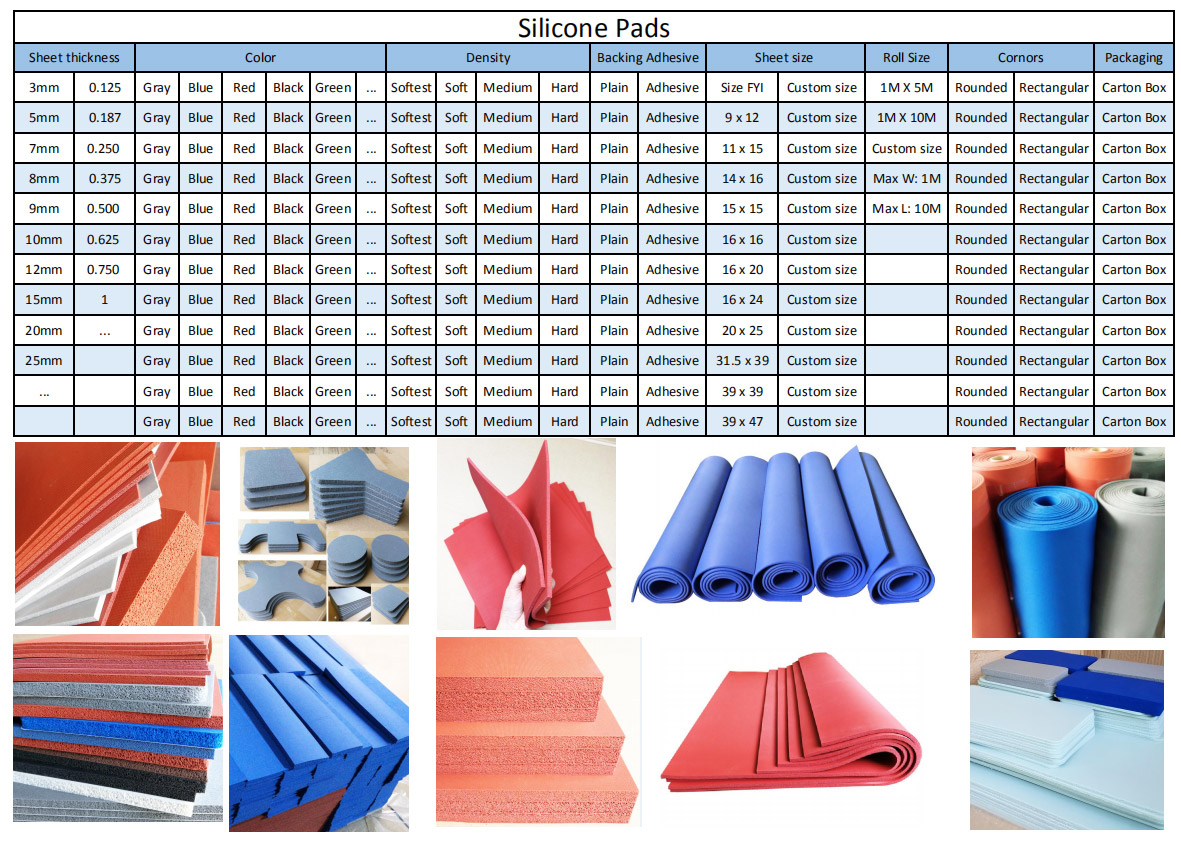

Moonus mainly offer closed cell (skinned) silicone sponge material in different size and densities.more specifications please check on our product details or email us.

Closed cell (skinned) silicone sponge offers many of the performance benefits associated with solid silicone, but in a softer and more compliant form. Silicone Sponge Sheet and strips are available in various sizes, densities, colors and with self-adhesive backing on request.

Key Benefits of Closed Cell Silicone Sponge

Wide operating temperature – silicone sponge has a temperature range of -40C to 250C

Water sealing – the closed cell structure allows for good water sealing with relatively low compressive forces.

Compression set resistance – silicone offers excellent compression set resistance (ability to rebound to original thickness), especially at higher temperatures, compared to most rubber material. Low compression set silicone sponges are available for even better performance than general purpose grades.

UV and ozone resistance – silicone products have excellent UV and ozone resistance due in part to their organic backbon

English

English

Russian

Russian